We’re here to set your mind at cheese….we mean, ease, with our guide to shipping this delicious gouda dairy product. Don’t let it brie, make sure you have the right packaging and processes in place so that nothing is feta than the cheese that gets delivered to your customers.

OK, enough with the cheesy puns and on to how to ship cheese in the right way. There’s no gruyere areas here, just grate ways to make sure that your cheese gets from A to B in the manner to which it wishes to be accustomed (we don’t want anyone’s cheese to arrive feeling bleu….OK, that’s all the puns done now, honest!)

Why does cheese need to be kept cold?

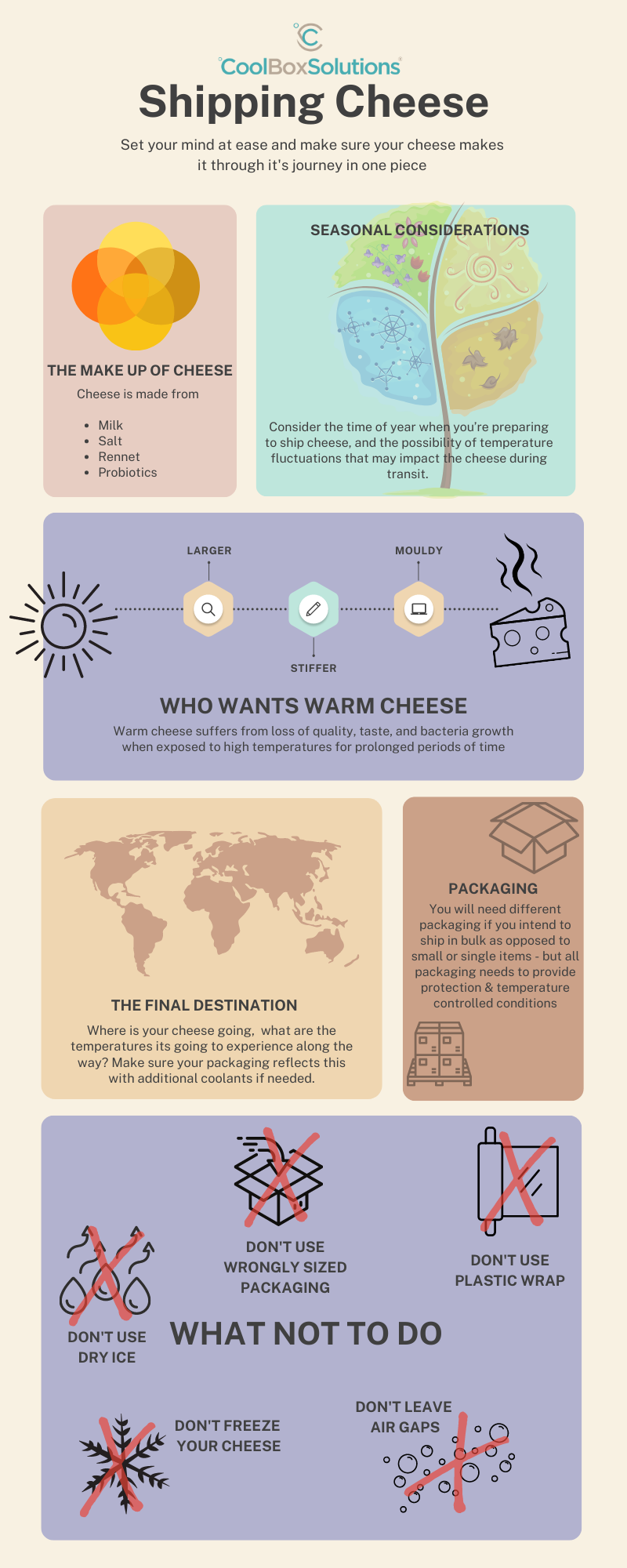

Cheese is made up of different ingredients, all of which have their own requirements in terms of storage and shipping. Whilst certain types of cheese contain flavourings and/or extra ingredients, the basic components of natural cheese are:

- Milk – milk must be kept cold at a temperature between 0 °C and 4 °C so that bacteria cannot grow and spoil the product.

- Salt – does not need to be kept chilled as it does not contain moisture or decay

- Rennet (an enzyme used to set cheese and make it coagulate until used

- Probiotics (“good” bacteria) – depends on the probiotic in question as to whether it needs to be kept cold.

As the majority of the ingredients that go into natural cheese need to be kept cold, it is important that the end result – the cheese – is kept at a refrigerated temperature. Some cheese, such as hard or semi-hard ripened cheese, can be kept at room temperature for longer than soft or fresh cheese (such as camembert or brie), but all in, cheese needs to be kept at a chilled temperature.

What happens if cheese gets too warm?

If cheese becomes too warm or is kept at warm temperatures for too long there are several things that can happen. For most types, this is a max of 4 hours but this does vary – some are less tolerant and others, especially hard cheeses, are more robust.

- Size increase – either of these can happen; the cheese may grow in size as it becomes warmer (which can then rip any wrapping on the cheese) and then it can shrink back once it is refrigerated again.

- Stiffer consistency – if cheese has become hot and then cold, it can shrink back down quickly as it has lost moisture. This means it is likely to be stiffer than normal, which impacts the end texture and taste for the consumer.

- Mould growth – bacteria love the heat, so cheese that is exposed to higher temperatures is likely to grow mould and spoil.

As with all products, the type of cheese in question will determine the full effects of high temperatures and how long these take to have an impact.

With this in mind, it is extremely important for anyone shipping cheese products to make sure they are kept at continual chilled conditions through the entire transport process.

Seasonal considerations

You should consider the time of year when you’re preparing to ship cheese, and the possibility of temperature fluctuations that may impact the cheese during transit. Even if you’re using a temperature controlled packaging solution, you need to be aware of how many ice packs are needed in conjunction with the outer packaging system to keep the cheese at a constant chilled temperature, and also how effective the packaging itself is going to be. Different materials also have different insulating properties, so this is certainly something to find out before you commit to any one system.

Spring/Summer

Shipping cheese during these warmer months will mean an increase in the number of coolants you need to use to keep the cheese cool, and it is worth making sure that the packaging system you’re using has good structural integrity, as any damage to the outer box will let the heat in. You want to be using something robust with plenty of room for your additional ice packs inside.

Autumn/Winter

As the weather cools down, the need for ice packs will decrease, although not vanish entirely. Damaged packaging in terms of heat is not such a concern, but you will still need to make sure your packaging system is strong enough to withstand any water related damage such as rain or snow.

Packaging in bulk or individually

You may only be shipping one or two cheeses, or you may be shipping in bulk – each require consideration for preservation and protection, but your packaging needs will vary depending on the amount of cheese going into the same box.

If you are sending only one or two items, then make sure they are packaged in appropriately sized boxes so they aren’t rolling around. Any gaps should be plugged with either ice packs or protective stuffing – we recommend keeping this sustainable and eco-friendly, such as scrunched up paper or cardboard which can be recycled, for example. This helps prevent against damage and also prevents any warm air from being trapped

If you are shipping your cheese in bulk, then again you need the right sized packaging, but the concern of the cheese rolling around in transit is less, because of the amount being shipped together. Most bulk cheese shipments are stacked and even tied together inside the packaging, with room for the ice packs. Small gaps should be plugged, but it isn’t such a critical need as when only shipping one or two pieces, as the cheese should be less able to move around and there will be less gaps for warm air to settle into.

The final destination

Not only do you need to think about when the cheese leaves you, you also need to think about where its going. Is it going to another country where the temperature conditions will be very different? Is it likely to be stored in a lorry or warehouse before it reaches its final destination? If there is an increased risk of the cheese becoming too warm due to extended transit times or hot conditions at the end of the journey, then your packaging should reflect this with additional coolants as precautions against heat spoilage.

You may also think that using the fastest courier option is the best, but this isn’t always the case as this can be very expensive and at some point these increased costs need to be met by either yourselves or passed down to the end consumer, which can impact buying decisions. As long as you pack the cheese properly and use enough coolants within the packaging, then using a courier who offers slightly longer transit times for a fairer cost will be fine.

What not to do

We’ve talked about what you should do when shipping cheese, but what about what not to do?

- Don’t use dry ice – this requires special handling, which can up the cost of transit considerably

- Don’t freeze your cheese – this impacts the quality of the cheese, making it less palatable for the end consumer

- Don’t use inadequately sized packaging – this can lead to damage either by squashing or giving too much room for the contents to move around inside. It also costs more to buy larger packaging boxes, so make sure you buy the right size for what you’re shipping.

- Don’t leave air gaps – as above, these can lead to warm air being trapped inside, making the coolants used less effective and raising the temperature quicker.

- Don’t store cheese in plastic – not only is plastic bad for the environment, it fosters a wet environment, which leads to mould growth and wet cheese. If you must wrap it in plastic to send it, include a note to the consumer that they should change the wrapping often and preferably use something more eco-friendly, such as reusable storage pots.

In conclusion, if you want your cheese to arrive feeling feta than ever, and make sure your customers aren’t left feeling bleu, then make sure you ship your cheese well, with the right packaging and the right number of coolants to ensure it arrives at its end destination in brie-llant condition!